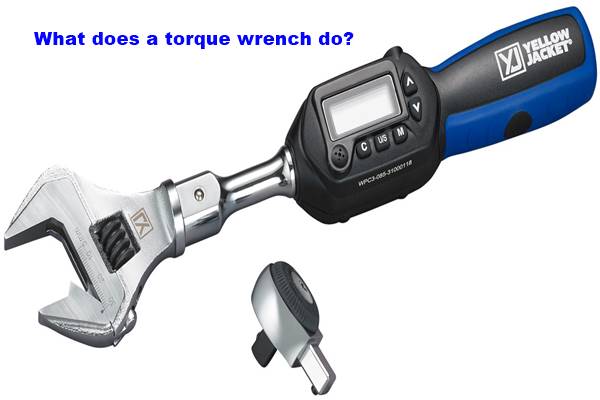

1. What does a torque wrench do?

A torque wrench is a tool used to apply a specific amount of torque (rotational force) to a fastener, such as a bolt or nut. This ensures that the fastener is tightened to the correct level, which is important for preventing over-tightening or under-tightening. Over-tightening can cause damage to components, while under-tightening can result in fasteners loosening over time.

2. What do I need a torque wrench for?

You need a torque wrench for tasks where precise torque measurements are required. Common uses include:

- Car maintenance: Tightening bolts, such as wheel lug nuts, to the manufacturer’s specified torque.

- Bicycle repair: Ensuring proper torque on components like pedals or handlebars.

- Mechanical work: Assembling parts in engines, machinery, or appliances where the correct torque is crucial for safety and functionality.

3. What are the 2 types of torque wrenches?

There are two main types of torque wrenches:

- Click-type Torque Wrench: This is the most common type. It provides an audible “click” when the desired torque level is reached, letting the user know it’s time to stop tightening.

- Beam-type Torque Wrench: This type uses a spring-loaded beam that bends as torque is applied. The user can read the amount of torque on a scale. It’s less common but still used in some professional settings due to its simplicity.

- Durable Ratchet Head: Made from Hardened treated Chrome Vanadium steel...

- Easy Storage: A sturdy plastic storage case is included. Non-Slip Grip:...

- Easy to Read: High Contrast & Dual Range Scale. Accurate: Pre-Calibrated to...

- Accessories included: 1/2" Drive 5" long Extension Bar

- Simple and Reliable: “Click” sound tells the preset torque value is...

- PORTABILITY: Torque wrench 1/2 inch drive has a durable case for...

- ADDED COMFORT: Bi-material handle for comfort and grip of the 1/2 torque...

- HASSLE FREE USE: Locking feature adjusts quick and easily for hassle free...

- QUICK IDENTIFICATION: Scales stamped into housing showing inch and metric...

- Meets or Exceeds ASME Specifications

- The entire set of tools is made of high-quality materials, including S2...

- Calibrated according to DIN 6789, 10 to 55 inch-pounds is pre-calibrated...

- The scale on this torque wrench screwdriver is clear, easy to read, and...

- This torque screwdriver has a wide range of uses and can be used for...

- 1 x high-precision preset torque screwdriver, 4 x Phillips bits: PH0, PH1,...

- PRECISE & HIGH QUALITY - Manufactured in Taiwan, our torque wrench is...

- DURABLE - Built to last, featuring a reinforced ratchet gear head made from...

- LONGEVITY - Protect your investment with our proprietary Electro-Black...

- PERFORMANCE - Easily read and set torque levels with our patent-pending...

- OMFORT - Equipped with a reversible ratchet head that drives in both...

- What You Will Receive: You will receive the 1/2-inch drive click torque...

- Good Quality and Durable Material: Made of hardened chromium vanadium steel...

- High Precision and Quick Reading: 1/2 torque wrench has high contrast and...

- Quick Torque Setting: Simple and fast torque setting, pull down the locking...

- Safe and Reliable Operation: Equipped with a bidirectional drive ratchet...

4. What is the 20 rule for torque wrenches?

The 20 rule for torque wrenches is a guideline to maintain accurate calibration of the wrench:

- When not in use, the torque wrench should be set to 20% of its maximum torque setting. This ensures that the internal spring mechanism does not stay under constant tension, preserving the wrench’s accuracy and extending its lifespan.

5. What are three rules of torque wrenches?

Three important rules to follow when using a torque wrench are:

- Calibrate Regularly: Ensure your torque wrench is calibrated regularly for accuracy. A wrench that is not calibrated can result in under or over-tightened fasteners.

- Use the Right Wrench for the Job: Choose a torque wrench that matches the torque specifications you need (e.g., low torque for smaller fasteners or higher torque for engine work).

- Don’t Use It as a Regular Wrench: Only use the torque wrench for tightening bolts to a specific torque value. Using it as a regular wrench can damage the mechanism and lead to inaccurate readings.

6. How much torque for tires?

The torque for tires depends on the vehicle’s make and model, but generally, the torque for tightening lug nuts is in the range of 80-100 ft-lbs (108-136 Nm). It’s always important to refer to the vehicle manufacturer’s recommendations for the correct torque to avoid damaging the wheel or studs. Using a torque wrench ensures the lug nuts are tightened properly, preventing them from loosening while driving or causing damage to the wheel assembly.

Who is the CEO of Being Human Clothing?

1. How do you know what size torque wrench you need?

The size of the torque wrench you need depends on the torque range required for the specific job you’re doing and the size of the fasteners you’re working with. Here’s how to choose:

- Torque range: Determine the minimum and maximum torque values specified for the task (e.g., tightening bolts or lug nuts on a car).

- For light-duty tasks (like bicycles), a torque range of 10-60 ft-lbs might be sufficient.

- For automotive work, you may need a wrench with a range of 20-150 ft-lbs or more.

- Drive size: Torque wrenches typically come in different drive sizes, usually 1/4 inch, 3/8 inch, 1/2 inch, and 3/4 inch.

- Smaller drive sizes (1/4″ or 3/8″) are suitable for lighter work, while 1/2-inch is the most common for automotive tasks.

Ensure the wrench’s torque range covers the requirements of your specific job.

2. How much does a quality torque wrench cost?

The price of a quality torque wrench can vary widely based on its brand, type, and range. On average:

- Entry-level torque wrenches: These generally range from $20 to $50. They are functional but may have less precise calibration or durability.

- Mid-range torque wrenches: These typically cost between $50 and $150. They offer better build quality, more accurate calibration, and are usually more durable.

- High-end torque wrenches: Professional-grade models, often used in automotive or mechanical work, can cost anywhere from $150 to $400 or more. These are highly accurate, durable, and often feature more advanced settings or digital readouts.

Investing in a mid-range to high-end wrench is advisable for more precision and long-term use.

3. What are the different types of torque wrenches?

There are several types of torque wrenches, each suitable for different applications:

- Click-type

- The most popular type. It “clicks” audibly when the set torque value is reached.

- Offers high accuracy and is easy to use.

- Common for automotive and general mechanical use.

- Beam-type:

- Simple, mechanical design with a beam that bends as torque is applied.

- The torque value is indicated on a scale on the beam.

- Less expensive but not as precise as the click-type.

- Digital or Electronic

- Uses digital technology to provide a precise torque reading.

- It often features a screen that displays the torque value in real time.

- These are high-precision tools, useful for tasks that require very accurate torque measurements.

- Torque Screwdriver:

- Smaller and used for low-torque applications, like precision electronics or bicycle maintenance.

- These are typically used for settings under 10 ft-lbs of torque.

4. What is a good accurate torque wrench?

A good and accurate torque wrench is one that provides consistent and precise torque measurements. Here are some recommendations for reliable brands known for accuracy:

- Craftsman (click-type or digital models): Offers a good balance between cost and accuracy, often within ±4% of the set torque value.

- Snap-on: A high-end, professional-grade brand known for precision and durability. Snap-on wrenches are highly accurate (usually within ±3%).

- Tekton: Known for budget-friendly, reliable torque wrenches with accuracy often within ±4%.

- Precision Instruments: Offers high-accuracy torque wrenches with consistent readings for professional use, with many models having ±3% accuracy.

A good accurate torque wrench will typically have a calibration tolerance of ±4% of the full scale. If you need extreme precision, look for models with tighter tolerances or consider a digital wrench, which often provides real-time feedback and higher accuracy.

1. What if I don’t have a torque wrench?

If you don’t have a torque wrench, here are some options:

- Estimate by feel: While not ideal, some people try to judge the torque by how tight they can get the bolt or nut by hand. This method is not recommended, as it’s easy to over-tighten or under-tighten, potentially causing damage or unsafe conditions.

- Use an alternative tool: You could use a regular wrench or ratchet with a hand-tightening approach, but you won’t get an accurate torque value. This may work for lighter tasks where exact torque isn’t critical, but it’s not a substitute for proper torqueing.

- Get the right tool: If you frequently need to apply specific torque, it’s best to invest in a torque wrench. They’re not terribly expensive, and using one ensures that you’re tightening fasteners to the correct specifications, improving both safety and longevity of the components.

2. What is the purpose of torquing?

The purpose of torquing a fastener is to apply a specific amount of rotational force to ensure the fastener is tightened properly. Here’s why it’s important:

- Prevent damage: Over-tightening can cause damage to the fastener or the components it holds, such as stripping threads or cracking parts. Under-tightening can lead to parts loosening over time due to vibrations.

- Ensure safety: In critical applications (e.g., car wheels, engine assembly), using the proper torque prevents failures that could lead to accidents.

- Proper function: Many fasteners, such as those in engines, machinery, or vehicles, need a certain level of torque to operate correctly. Too much or too little torque can affect performance or durability.

3. What is the disadvantage of torque wrench?

While a torque wrench is an essential tool for many tasks, it does have a few disadvantages:

- Cost: High-quality torque wrenches, especially professional-grade ones, can be expensive.

- Calibration: Torque wrenches need to be regularly calibrated to maintain accuracy. Over time, they can lose their calibration, leading to inaccurate readings.

- Learning curve: It can take time to learn how to use a torque wrench correctly, especially with click-type or digital models. Incorrect usage (e.g., not setting the correct torque value) can result in errors.

- Bulkiness: Torque wrenches can be larger and heavier compared to standard wrenches, making them less convenient for tight spaces or small tasks.

4. Will a torque wrench keep tightening after clicking?

No, a click-type torque wrench is designed to stop tightening once the set torque value is reached, and the “click” sound is an indication that you should stop applying force. After you hear the click, continuing to apply force will not increase the torque and could potentially damage the wrench or the fastener. However, clicking too early (before reaching the proper torque) can lead to under-tightening, so it’s important to listen for the click only when the wrench is in the correct position and tension.